Lumber supply for luxury custom home builders

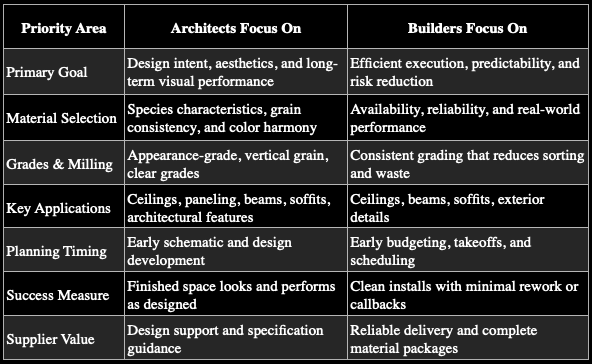

This page outlines how luxury custom home builders source high quality appearance-grade lumber, focusing on species selection, grade consistency, installation efficiency, and planning strategies that reduce waste, delays, and callbacks.

Ideal Use Cases

Exposed interior finishes where material quality is immediately visible

Ceilings, beams, soffits, and exterior architectural details

High-end residential projects with tight quality expectations

Custom homes where reduced waste and callbacks are critical

Species Recommendations

Western Red Cedar for reliable performance across interior and exterior applications

Alaskan Yellow Cedar for interior, exterior, and moisture-prone environments

Hemlock for straight, clean interior installations

Douglas Fir for structural and decorative beam applications

Redwood for exterior use in coastal or high-moisture conditions

Grade Guidance

High quality appearance-grade lumber to minimize sorting and jobsite waste

Consistent grain and color matching across material packages

Vertical grain for improved stability, modern look, and finish performance

Clear or Select Tight Knot grades depending on exposure and client expectations

How to Source and Plan

Engage the lumber supplier during early budgeting and takeoff stages

Confirm quantities, profiles, and delivery sequencing in advance

Order material as a complete package to ensure consistency

Schedule delivery to align with framing, finish, and install timelines

What makes a lumber supplier suitable for luxury custom home builders?

A suitable lumber supplier for luxury custom homes and commercial buildings provides consistent high quality, appearance-grade materials, reliable lead times, and a clear understanding of high-end residential construction requirements. Predictability, communication, and material quality are critical at this level.

Why do builders prefer appearance-grade lumber on custom projects?

High quality appearance-grade lumber reduces job site waste, sorting time, and installation issues. Builders benefit from straighter material, consistent profiles, and predictable finishes, which help maintain schedules and minimize callbacks on high-visibility installations.

Which applications benefit most from premium softwood lumber?

Premium softwood lumber is most valuable in exposed applications such as ceilings, wall paneling, beams, soffits, siding, and exterior architectural elements. These areas demand both visual consistency and long-term performance.

How does premium lumber reduce long-term risk on custom homes?

Premium lumber lowers the risk of warping, checking, uneven finishes, and customer dissatisfaction. By using high quality appearance-grade materials, builders protect both their craftsmanship and their reputation on high-end projects.

When should builders engage their lumber supplier during a project?

Builders should engage their lumber supplier early to coordinate quantities, profiles, species selection, and delivery timing. Early collaboration helps avoid substitutions, delays, and material mismatches during construction.